A Flexible, Safe, and Reliable Low Voltage Power Distribution Solution

A Flexible, Safe, and Reliable Low Voltage Power Distribution Solution

The Busway BL Series from Delta are made from epoxy using vacuum casting. Superior to traditional cables or sandwich type busway solutions, Delta’s Busways significantly improve the protection ratings, safety and reliability of products, are ideal for use in harsh environmental conditions, and can be extensively applied to a range of industries. Thanks to the outstanding electrical and mechanical properties of resin, these busways have reduced dimensions, a simplified structure, extended service life, and improved reusability. More importantly, Delta’s Busways provide excellent energy-savings to help our customers enjoy substantial savings on their electricity bills.

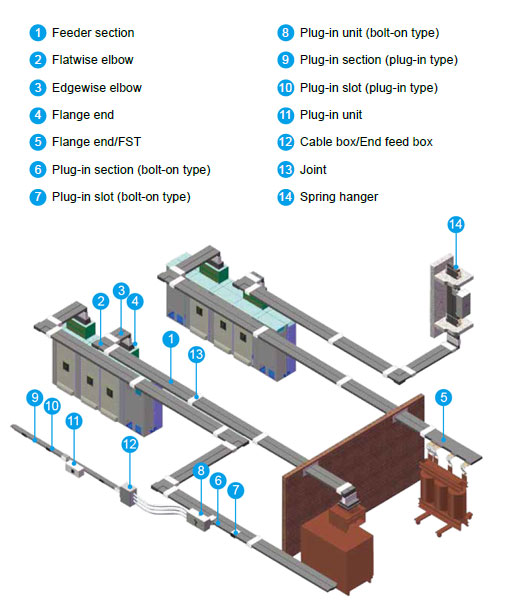

System Architecture

Product available regions :

| North America |

Latin America |

| 250-5000 A (UL) |

400-6400 A |

|

Downloads (EN) Request a Quote Subscribe Newsletter