In a global economy, Packaging Machine builders face complex demands like sustainability, reducing capital equipment costs, increasing Operational equipment effectiveness and competing with competition in cost.

Delta Industrial Automation provides complete solutions for machine automation with the performance, flexibility and simplicity needed to meet these complex challenges of Packaging machinery OEMs and end users.

Unique parameterized motion control functions built into the A2 Series Servo Drive takes advantage of distributed control technology to quickly solve common applications found in Stand-Alone Packaging Machinery. The synchronous pass-through feature produces fast dynamic correction capability for achieving precise positioning in eCAM & eGEAR implementations. As a result, motion is more smoothly controlled, damage to mechanical structures and maintenance costs are minimized, downtime due to material deformation is greatly decreased, and productivity is increased.

Delta's

C2000,

MH300 and

MS300 AC Drives as well as the

TP70P HMI product comes complete with a fully programmable internal PLC also suitable for stand-alone machinery. When higher levels of coordinated system control and flexibility are required, Delta’s wide range of modular controllers including the compact DVP Slim series and the rack-based

AH series PLC models extend the scalability suitable for Advanced Industrial Machinery requiring centralized control architectures.

Benefits of Delta Industrial Automation

|

Scalable -Scalable Control modules for stand alone machinery to complex machine systems or line control with stringent motion and visualization requirements.

|

|

Flexible - Centralized Control flexibility with the wide range of plug-in modules and Distributed Control flexibility with built-in PLC capability of each intelligent device.

|

|

Portable - Software program code that can be ported from the smallest slim-style SS2 PLC CPU to the most flexible AH500 rack advanced PLC and also to intelligent AC drives, Servos and HMI.

|

|

Speed – Programmable controllers and motion control devices connected to the fastest EtherCAT network delivering speed and performance. |

Smart Manufacturing for the Packaging Industry

As a major contributor to Industry 4.0 and Smart Manufacturing, Delta offers IIOT ready Industrial Automation devices to the Packaging Industry along with Cloud routers and gateways for cloud connectivity to desktop or mobile devices. Built-in features make monitoring devices easy, such as SMS and email alarm smart functions. With over 15 servers across the globe and store-and-forward technology – reliability, speed and robustness are insured at the platform level with DIACloud.

| |

| |

|

| |

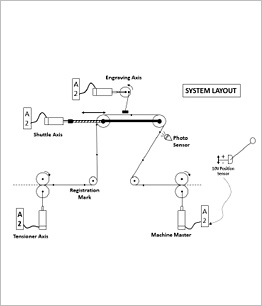

Delta A2 Servo drives with onboard control plus integrated HMI eliminate the need for a PLC on a film handling module.

Delta A2 Servo drives with onboard control plus integrated HMI eliminate the need for a PLC on a film handling module. |

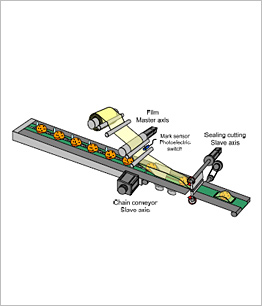

Delta solution for wrapping machine using eCAM, high speed registration, and built-in sequencing for coordinated servo control.

Delta solution for wrapping machine using eCAM, high speed registration, and built-in sequencing for coordinated servo control. |

| |

|

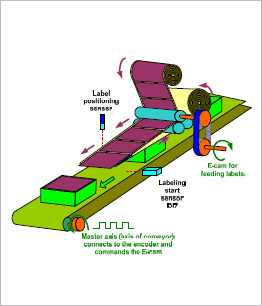

Delta solution labeling module to index labels or parts onto a moving conveyor – with speed matching and dynamic conveyor position tracking.

Delta solution labeling module to index labels or parts onto a moving conveyor – with speed matching and dynamic conveyor position tracking. |

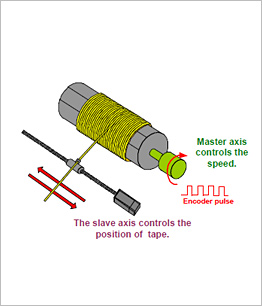

Delta solution for coil winding with wind and travers axis performing tight position control to insure tight winding and custom end-turn wire lay.

Delta solution for coil winding with wind and travers axis performing tight position control to insure tight winding and custom end-turn wire lay. |

| |

|

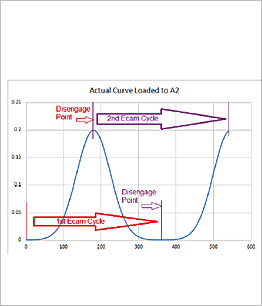

How to create custom curve profiles using eCAM and sequencing in the A2 Servo Drive. Dynamically adjust the frequency and curve shape for batch counted move sequences.

How to create custom curve profiles using eCAM and sequencing in the A2 Servo Drive. Dynamically adjust the frequency and curve shape for batch counted move sequences. |

Control torque-down station with trigger points for verifying quality or rejects, and examples of building a control buffer.

Control torque-down station with trigger points for verifying quality or rejects, and examples of building a control buffer. |

|

|

| |

|

| |

| |

|

| |

Complete machine control provided by Delta’s Integrated Automation Solutions for Packaging Machinery.

Complete machine control provided by Delta’s Integrated Automation Solutions for Packaging Machinery. |

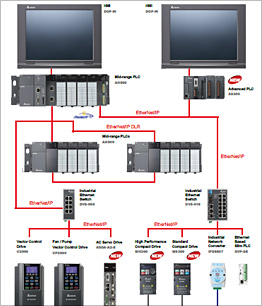

EtherNet/IP connectivity providing component and system level advantages visible at PLC machine module and line level production.

EtherNet/IP connectivity providing component and system level advantages visible at PLC machine module and line level production. |

| |

|

Highly functional product technology with built-in functions to solve application specific solutions, and reduce overall equipment costs for machine modules.

Highly functional product technology with built-in functions to solve application specific solutions, and reduce overall equipment costs for machine modules. |

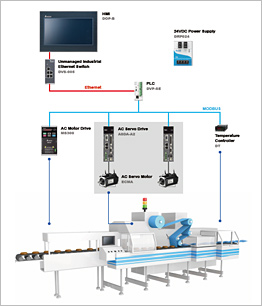

Machine and line automation with centralized PLC connected to AC Drives, Servo Systems, Remote I/O stations, Sensors, Vision Systems, and Robotics.

Machine and line automation with centralized PLC connected to AC Drives, Servo Systems, Remote I/O stations, Sensors, Vision Systems, and Robotics. |

| |

|

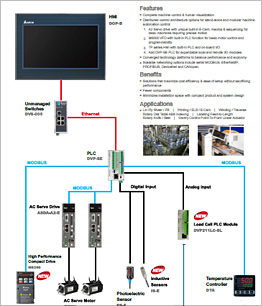

Scalable architecture solutions for Food Packaging ranging from Stand-alone distributed control to flexible centralized system.

Scalable architecture solutions for Food Packaging ranging from Stand-alone distributed control to flexible centralized system. |

|

|

|

| |

|

|

| |